- Contact Person : Mr. Yuan John

- Company Name : Shanghai Lanmao International Trade Co., Ltd.

- Tel : 86-21-66988789-8002

- Fax : 86-21-66988978-8007

- Address : Shanghai,shanghai,No.3135,Changzhong Road,Zhabei District

- Country/Region : China

- Zip : 200072

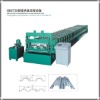

Steel sheet roof machine

Steel sheet roof machine

Product Feature:

steel tile forming machine,tile forming machine, roof tile machine, roof tile making machine to make steel tiles look beautiful ,elegant and noble.They are widely used as the roof of garden,factory,hotel,exhibition center and villa,etc. Roll forming machine |

Machine's components:

Tile forming machine consist of uncoiler,coil sheet guiding and adjusting device,covering film device,main roll forming system,pressing device,cutting device,hydraulic station,PLC control system and support table.roof panel roll forming machine

Main technical parameters:

Tile forming machine

1.Suitable material:color steel sheet

2.Thickness of raw material: 0.5-0.6mmGlazed tile roll forming machine |

3.Yield strength of material: 235Mpa

4.Working speed: about 15-20m/min

5.Step distance: adjustable according to requirement(≥250mm)Forming machine |

No | Item | Parameter | Note | |

1 | Suitable Material | Type | Pre-paint Steel Aluminum | |

Width | According to profile | |||

Thickness | 0.30—0.70mm | |||

2 | Product Specs | Cover width | According to profile | Refer to drawing |

Wave height | According to profile | |||

Length | Any length | |||

3 | Machine Material | Active shaft | No. 45 steel tempered | Up to final design |

Roller | No. 45 steel chrome plated | |||

Cutting Blade | Cr12 quenched | |||

4 | Power Requirement | Type | 380V/3PH/50HZ | Customized |

Main motor | 5.5kw | Up to final design | ||

Hydraulic | 5.5kw | |||

5 | Speed | Production speed | Max 6m/min | Includes cutting & punching |

6 | Hydraulic Cantilever Decoiler | Type | Hydraulic | |

Max. capacity | 5000kgs | |||

Suitable coil OD | 1200mm | |||

Suitable coil ID | 508/610mm | |||

Max Coil width | 1250mm | |||

Motor power | 3kw | |||

Hydraulic Power | 2.2kw | |||

7 | Forming Stand | About 20 group | Up to profile | |

8 | Transmission style | Chain, sprocket | Double row Entire chain | |

9 | Main machine structure | Guide Column | ||

10 | Type of Cutting | length-set cutting | Hydraulic cutter | |

11 | Control System | Mitsubishi PLC& transducer | ||

12 | Product support | Automatic stacker/ Simple run out table | ||

Steel sheet roof machine